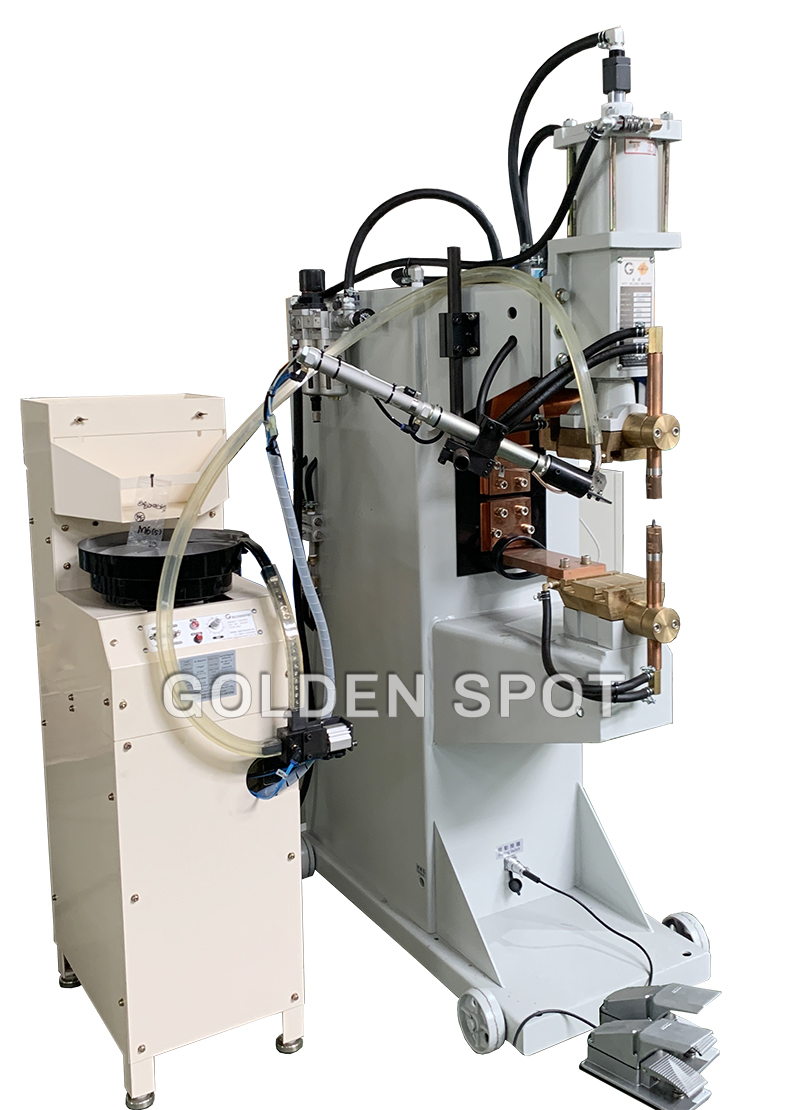

Auto Nut Feeding Welding Machine Model:SA-1000VT

I. Auto Nut Feeding Welding Machine

(Equipped with Vibratory Bowl Feeder.)

II. Auto Bolt Feeding Welding Machine

(Equipped with Vibratory Bowl Feeder.)

Welding Items

Inquiry

Automatic Nut Feeding Spot Welding Machine

-

Function and Principle

- The automatic nut feeding spot welding machine is a high-efficiency, automated welding device designed to quickly and precisely weld nuts onto metal plates or parts.

- It operates by using an automatic feeding system to deliver nuts to the welding position, then applies spot welding technology to securely attach the nut at the designated location.

- Spot welding technology uses two electrodes to generate high heat between the nut and base material, causing the contact surface to melt and fuse together.

-

Application Fields

- Widely used in industries such as automotive, home appliances, and machinery manufacturing.

- It significantly improves production efficiency, reduces labor costs, and ensures welding quality.

-

Advantages

- The automatic feeding spot welding machine replaces traditional manual welding, enabling continuous and automated operation with reduced error rates.

- It can complete high-precision, large-scale welding tasks in a short time, providing consistency and reliability.

-

Core Components

- Feeding System: Automatically distributes nuts to the welding position.

- Positioning Device: Ensures accurate nut placement during welding.

- Spot Welding Mechanism: Performs stable welding operations, ensuring strong and secure welds.

-

Technological Development and Prospects

- With advancements in automation technology, the machine has become increasingly intelligent.

- It greatly enhances welding efficiency and quality stability, making it an essential device in modern industrial production.